College of Engineering

Collaborative robot 'Sawyer' to give manufacturing engineering technology students a helping hand in learning robotics

Cookeville, TN—Tennessee Tech manufacturing engineering technology students will see a friendly new face in the lab this fall, and his name is Sawyer.

A one-armed robot with animated human features, the Sawyer Robot System and Pedestal is a cobot, or collaborative robot, donated to the College of Engineering by Centro, Inc., a Memphis-based company that supplies control and automation product solutions to the manufacturing industry. Centro is a distributor for Rethink Robotics, which developed one of the first collaborative robots a decade ago to work alongside humans in industrial processes.

Because Centro works with manufacturing companies to advance their manufacturing processes, the company is deeply familiar with the emerging importance of cobots in industry and the pace of technological change—as well as the need for an engineering workforce with hands-on experience with robotics.

“The manufacturing industry is constantly evolving and industrial automation via the use of robotics is growing in popularity at record rates,” said Jerry Walling, Automation & Robotics Division Sale Manager for Centro, Inc. “Therefore, Centro wanted to do our part to ensure that students are getting hands on opportunities with real life, industrial robots while they’re in college.”

Tennessee Tech’s College of Engineering is well known for its career-ready graduates, with several working for Centro’s customers, the company said. “Centro wanted to donate a collaborative industrial robot to the College of Engineering at Tennessee Tech University because our customers hire countless, highly talented Tech alumni,” Walling said. Centro has nine locations serving the Mid-South portion of the United States.

Sawyer enhances two courses in Industrial Automation and Robotics, and Applied Mechatronics,

providing Tech’s engineering students with an important skill in the practical operation

of cobots, according to Duckbong Kim, Ph.D., associate professor for manufacturing

engineering technology. “This will transform students into more competitive, 21st-century technicians, engineers and managers,” he said. “Since this collaborative

robot can perform several operations (machine tending, pick-and-place, gluing-and-labeling,

parts assembly, and parts inspection), it is widely used in many industries, such

as automotive, healthcare, medical, and manufacturing.”

Sawyer enhances two courses in Industrial Automation and Robotics, and Applied Mechatronics,

providing Tech’s engineering students with an important skill in the practical operation

of cobots, according to Duckbong Kim, Ph.D., associate professor for manufacturing

engineering technology. “This will transform students into more competitive, 21st-century technicians, engineers and managers,” he said. “Since this collaborative

robot can perform several operations (machine tending, pick-and-place, gluing-and-labeling,

parts assembly, and parts inspection), it is widely used in many industries, such

as automotive, healthcare, medical, and manufacturing.”

Before cobots existed, industrial robots did not work side-by-side with people, operating instead behind cages or protective barriers. They also typically served a single purpose. A cobot such as Sawyer—with its small footprint, a 7-degree-of-freedom arm with a 1,260-millimeter reach, multiple attachments, sensing capabilities, camera data, and interactive programming—can work safely and precisely in human spaces doing more repetitive tasks, such as inspection and picking, so workers can focus more on problem-solving and critical thinking. Students will learn not only how to program and use Sawyer and his many “hand” grip attachments, but also how cobots’ artificial intelligence can make processes more efficient.

The arrival of Sawyer to Tech’s campus is a milestone in Kim’s efforts to build a robust smart manufacturing and data analytics program in the college, he said.

“It is widely acknowledged that smart manufacturing and data analytics are the two pillars in advanced manufacturing and engineering industries in terms of future innovation and providing the important foundations for gaining industrial competitiveness and ensuring economic success,” particularly in Tennessee, he said. Kim plans to create new curriculum, labs, certifications and research partnerships to create a cross-disciplinary workforce development model to serve the needs of industry across the state.

“With human-robot collaboration quickly becoming the norm in manufacturing, Centro’s generous donation of Sawyer will enable our students to have experience with cobots and hit the ground running when they enter the workforce, just as companies are implementing them at scale,” said Joseph C. Slater, dean for the College of Engineering. “These partnerships help us put our engineering students first, providing them industry-grade, interdisciplinary experience and research opportunities in our labs and classrooms that directly benefit employers. We look forward to seeing what our students do with robotics in the future.”

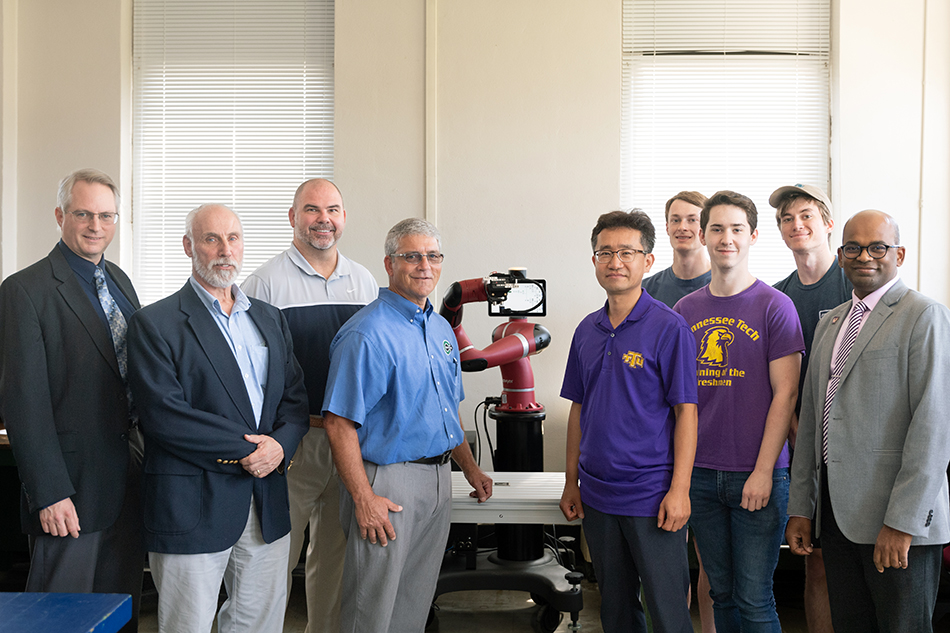

Photo credit (pictured left to right): Joseph C. Slater, dean, College of Engineering; Fred Vondra, chair, Department of Manufacturing and Engineering Technology; Jerry Walling, Automation & Robotics Division Sales Manager, Centro, Inc.; Paul Bateman, Territory Manager, Centro, Inc.;

DuckBong Kim, associate professor, Department of Manufacturing and Engineering Technology; Blake Brown, May 2022 graduate, manufacturing and engineering technology; Wayne Marcrum, junior, electrical and computing engineering; Nathan Bangean, junior, mechanical engineering; and Kumar Yelamarthi, associate dean of academic affairs, College of Engineering.