Tennessee Tech research focusing on improving implant and surgical processes

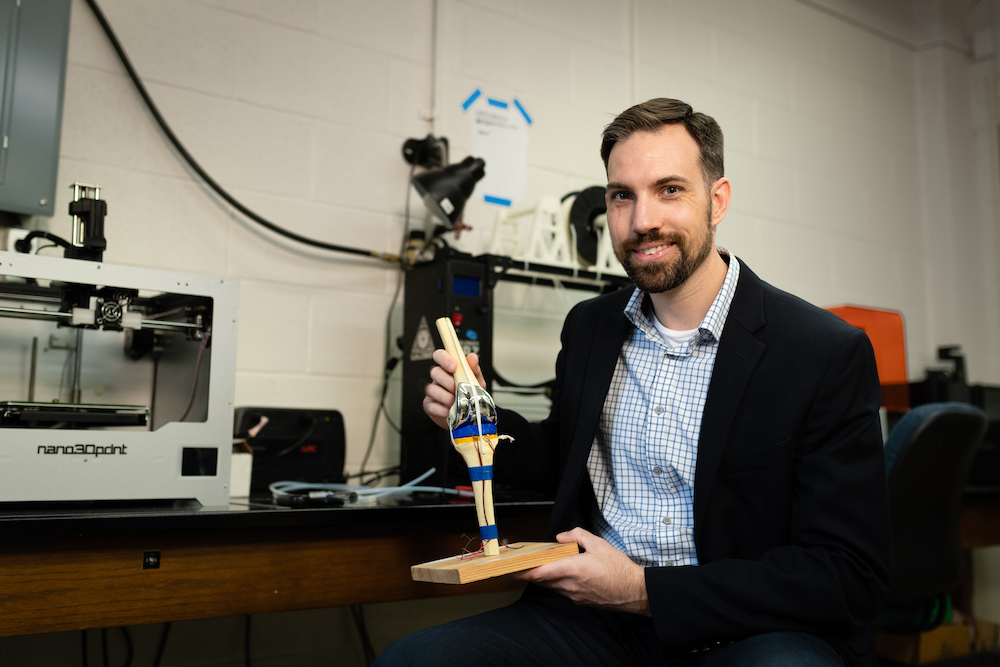

In the Dynamic and Smart Systems Lab at Tennessee Tech, Associate Professor of Mechanical Engineering Steven Anton and his students are taking a closer look at implant systems and the materials used for those implants to find ways to improve surgical processes.

“The particular research that I'm working on is involving the integration of smart materials into knee replacements,” Anton said.

Anton is actively collaborating with an orthopedic surgeon who works in the area of knee and hip replacements, integrating smart materials and machine learning in ways that could ultimately benefit patients.

For patients who receive a knee or hip replacement, this could mean improved lifespan of the replacement but also could provide real-time reporting of knee and hip health to better make medical decisions.

With the piezoelectric materials Anton works with, force or stress on the replacement materials can generate electrical energy to provide needed power to replacement parts, and sensors in the replacement can wirelessly transmit data to a patient’s care team.

“So, you can envision if I have the sensor in my knee, just walking through my house, it can collect data. When I go to bed at night, it can transmit wirelessly to a computer or even a tablet or my phone sitting on my bedside table, and that can get connected back to the hospital, back to the surgical team or the nurses. They can look at the data and see if anything's going wrong or make sure everything's going right.”

In the lab, Anton and his students use 3-D printed prototypes to better understand the practical applications of these implant sensors and systems.

For students, that means opportunities from the undergraduate to Ph.D. levels to be involved in research. In addition to the many graduate students Anton works with, he typically has two undergraduate students working with him.

“Currently, I'm working on the development of 3-D printed capacitative sensors,” explained

Andrew Gothard, a senior who has been involved in research at Tech since his freshman

year. “Specifically, why we're interested in the 3-D printing development of these

sensors is because people with any kind of foot deformities have trouble using regular

insoles. Typically, you can only adjust maybe size or something like that, but using

3-D printing, you can print customized insoles. You can do this according to a person's

3-D scan of their foot and then make it customized to their use, their foot. Then,

you can use the sensors to sense their gait and things like that.”

Brandon Miller, an Oak Ridge, Tennessee native who graduated from Tech in May, had the opportunity to work in the lab with Anton, focusing on the machine learning algorithms that process data from these types of sensors.

“Dr. Anton is a brilliant researcher and we have spent a great deal of time, especially recently, pouring over research, pouring over my data and trying to figure out what of this is good, and what of this needs revising in terms of the test plan. That’s been a really great experience,” Miller said.

Ultimately for or Anton, his work at Tech combines his interest in working with students with his implant systems research.

“That's really the heart of a lot of the work that I do is gaining a better understanding these implant systems, how they behave, how they function, so that ultimately we can improve surgical procedures as well as implant designs,” Anton said.