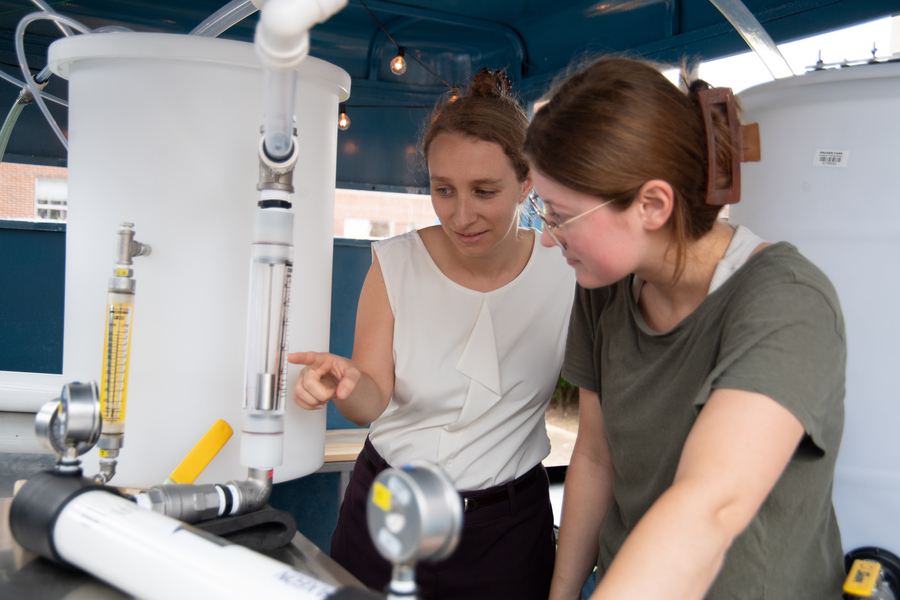

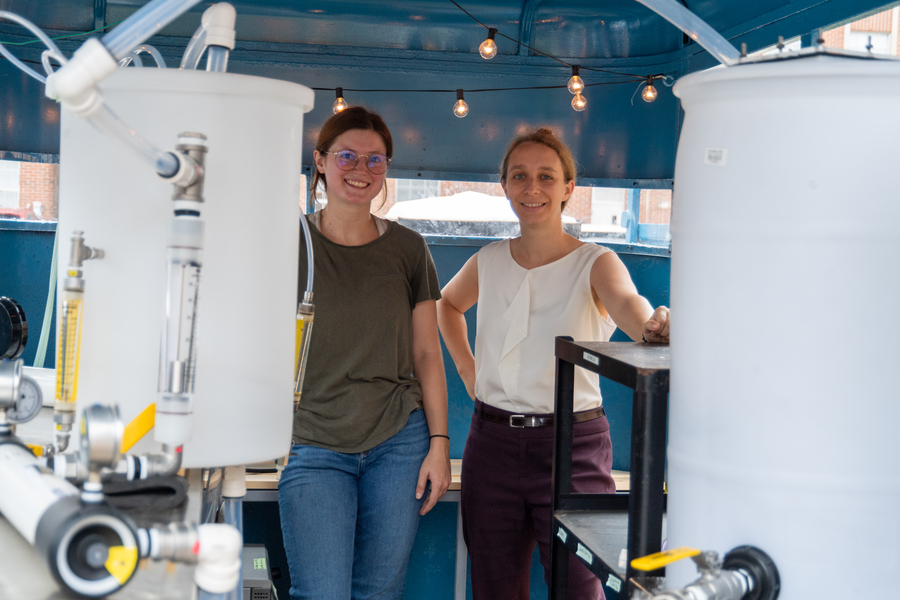

Laura Chavez and Catherine Murphy

Often in manufacturing, power generation and other similar industries, water is a

byproduct of the systems used. In some cases, these processes introduce molecules

into the water that make it unsafe to be returned into the main water supply. Tennessee

Tech University students and faculty are piloting an experimental process designed

to make this “process water” a source of valuable resources instead of hazardous waste

with costly disposal requirements.

Often in manufacturing, power generation and other similar industries, water is a

byproduct of the systems used. In some cases, these processes introduce molecules

into the water that make it unsafe to be returned into the main water supply. Tennessee

Tech University students and faculty are piloting an experimental process designed

to make this “process water” a source of valuable resources instead of hazardous waste

with costly disposal requirements.

“I would say all of the materials in the process water, if you could separate them out to perfect purity, would have useful roles in society,” Laura Arias Chavez, assistant professor of chemical engineering at Tech, said. “For example, we use lots of energy to make ammonia for fertilizer. Well, there's ammonia in this water. The idea is to try to figure out if there is a way that we can separate this process water on site so that we get a number of useful additional products out of it that otherwise might be deemed hazardous waste because they just happen to be mixed together.”

Along with ammonia, the process water that Chavez and her team work with contains a variety of hydrocarbons. These molecules could negatively affect human health and the environment if allowed to enter natural water bodies or drinking water supplies. However, these same molecules, if isolated from the water, could provide energy as part of diesel fuel or be sold as feedstocks to chemical processing plants. Whether these materials are a problem or a resource depends on how well they can be separated from the process water.

“Instead of generating something and then having it go as waste, we want to see how we can reclaim that as something that has value and continue to use it for society,” Chavez said. “We're trying to make better use of the limited water and energy resources that we have as a society that are going to become increasingly pinched and scarce as our global population increases.”

The first upscaled tests of the process started this fall semester, but the brainstorming of the project started years ago when Chavez and other faculty connected with a startup company in Lenoir City, Tennessee named Proton Power. The company, founded in 2005, uses clean energy techniques to turn certain agricultural crops and other bio-based materials into synthetic fuel or electricity.

Many of these crops can be grown in Tennessee, which raises the possibility that Tennesseans could produce significant quantities of diesel fuel, electricity and other energy products if this technology could be implemented more broadly. Process water is one of the byproducts of the chemical reaction that happens in Proton Power’s reactors.

Traditional ways of treating this type of water involve large, complex wastewater plants that destroy the residual hydrocarbons, ammonia and other molecules found in the process water. Constructing such plants is costly and running them requires significant energy. Chavez and her team are working to make the process more cost-efficient and therefore a more attractive option for businesses.

“We get results in the lab and we do some extrapolation with that,” Chavez said. “Then we adjust what we're doing in the lab to try to get to something that, in the end, is going to be not just technologically feasible, but economically feasible. That's why this pilot is so important, because we might come up with something in the lab that can separate out these components in the water. But if it takes more energy to do it than it would have to make them the conventional way, then that’s not something that we want to do.”

Chavez started working on small-scale experiments in 2015 with two undergraduate students. The following year, she started working with graduate students once the project was awarded funding from the National Science Foundation. Chavez also repeatedly recruited teams of senior-year chemical engineering undergraduates to take data from small-scale experiments and use that to design full-scale plants and predict their performance.

Chavez credits Tech’s Water Center, technicians from the Department of Chemical Engineering and College of Engineering, and faculty from Chemical Engineering and Chemistry as important partners who helped provide access to critical equipment and additional training to students. Many graduating seniors have gone on to pursue careers in water and wastewater after working on this project with real-world importance.

Now, a scaled-up pilot test is being done at Proton Power’s facility. Chavez is working with chemical engineering graduate student Catherine Murphy and a few undergraduates to take turns taking water samples on-site, watching the flow rate and making sure the system is stable 24 hours a day for 14 days straight. The purity of the reclaimed streams and the energy needed to run the system will be some of the many performance measures that the team will use to determine the next steps for their system.

For Murphy, the whole process has been a hands-on lesson in not only working with membranes and water purification techniques but also a lesson on how ideas go from small-scale research and experimentation to large-scale testing

“It’s been a great experience for me,” she said. “Whatever job I go into, there's always going to be something that needs to be built, and everything always has to be tested first at a smaller scale. So, I’m not only learning bench scale but also learning how to upscale a system from small to larger. Being able to fully construct it from start to finish, watch it run and doing all the minor fixes or major fixes – it’s been really helpful.”

Sam Weaver, Ph.D., president of Proton Power, added, “The Tennessee Tech team headed by Dr. Chavez has made outstanding progress developing a process to clean up our water co-products using cutting-edge technology. The approach was far from the standard and required a dedicated team to utilize the latest technology, which they developed. The Tennessee Tech team is a pleasure to work with, keeping Proton Power informed every step of the way."